SmartPack: Robotic Packaging Solution of Granules and Powders according to Industry 4.0

If you are looking for a highly efficient and innovative solution for packaging powders and granules, SmartPack is the perfect choice for you.

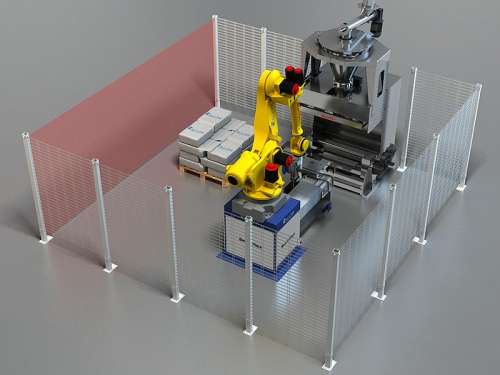

The SmartPack system represents a revolution in the world of powder packaging, industrial bag sealing, welding, and palletizing, based on the most advanced robotic system in the world.

SmartPack is a fully robotic bagging system for powders and granules, designed to perform multiple functions in a single robotic unit, including dosing, filling the bag with extreme precision, sealing or stitching the filled bag, and palletizing it. Moreover, thanks to its flexibility, this powder packaging system allows for instant changes in bag format and material, and it can handle multiple bagging heads with the same robot, even enabling simultaneous bagging of multiple products with the same setup.

Granules and Powders Packaging Machine: Features of SmartPack

The SmartPack bagging system for powders and granules is a highly innovative, flexible, and customizable packaging and palletizing system that optimizes production lines and enhances competitiveness in the market. Let's take a look at some of its key features for increasing efficiency and productivity:

- Fully robotic and highly efficient system for managing the entire packaging and palletizing process.

- Compact layout that enables installation in limited space environments or on movable and relocatable platforms. Furthermore, thanks to the versatility of the anthropomorphic robot, the layout can be easily reconfigured by relocating destination pallets, empty bag retrieval trays, and dosing heads.

- The powder dosing system can be based on gross weight, net weight, auger, gravity, turbine, or vibrating channel.

- SmartPack can be customized and configured according to specific customer needs, including the choice of dosing type, bag format, palletizing method, and more. Its flexibility and versatility make it suitable for various sectors, including food, pharmaceutical, chemical, and processing industries.

- The advanced technology of the robotic granules packaging machine ensures consistent and uniform production, minimizing packaging errors and ensuring high-quality finished products.

- SmartPack is fully developed on a robotic platform and natively configured with the SmartPack4.0_Protocol_Light protocol, which facilitates the system's certification process in accordance with "Industry 4.0" guidelines.

- The system is easily manageable by inexperienced operators, thanks to the advanced graphical interface.

- The granules packaging machine is designed with great attention to ease of cleaning.

Two Versions of Powder Packaging Machines

The system is available in two types of bag configurations, with various customizable base configurations to meet the needs of each customer.

- Bagging machine for powders and granules with valve bags and gross weight or net weight dosing system.

- Bagging machine for powders and granules with open-mouth bags and gross weight or net weight dosing system. It is also possible to install a vertical tube filling device for "bottom-up filling" for particularly dusty or difficult-to-handle products.

In general, powder packaging machines are essential tools for food and chemical companies that produce powdered or flowing granular materials such as bakery premixes, additives, spices, raw materials, plastic pellets, hot melt glue pellets, cereals, and other food and chemical ingredients. Thanks to their precision and ability to accurately control the quantity of material in each bag, even of different sizes and shapes, these machines ensure consistent and uniform production, efficiently managing large volumes of products while minimizing downtime.